Press Brake Supplier in China: Industry Expert with 20 Years Experience.

TENGZHONG Helps You Solve Mine Problems in The Most Time-saving, Labor-saving and Money-saving Way.

- Electrical Service Support

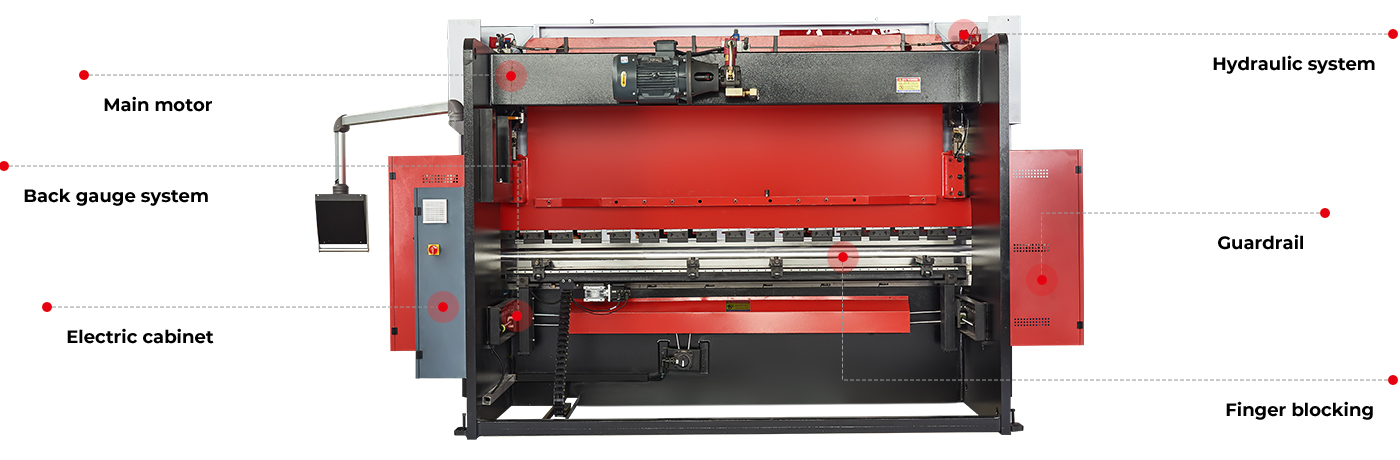

- Long Machine Life

- No MOQ

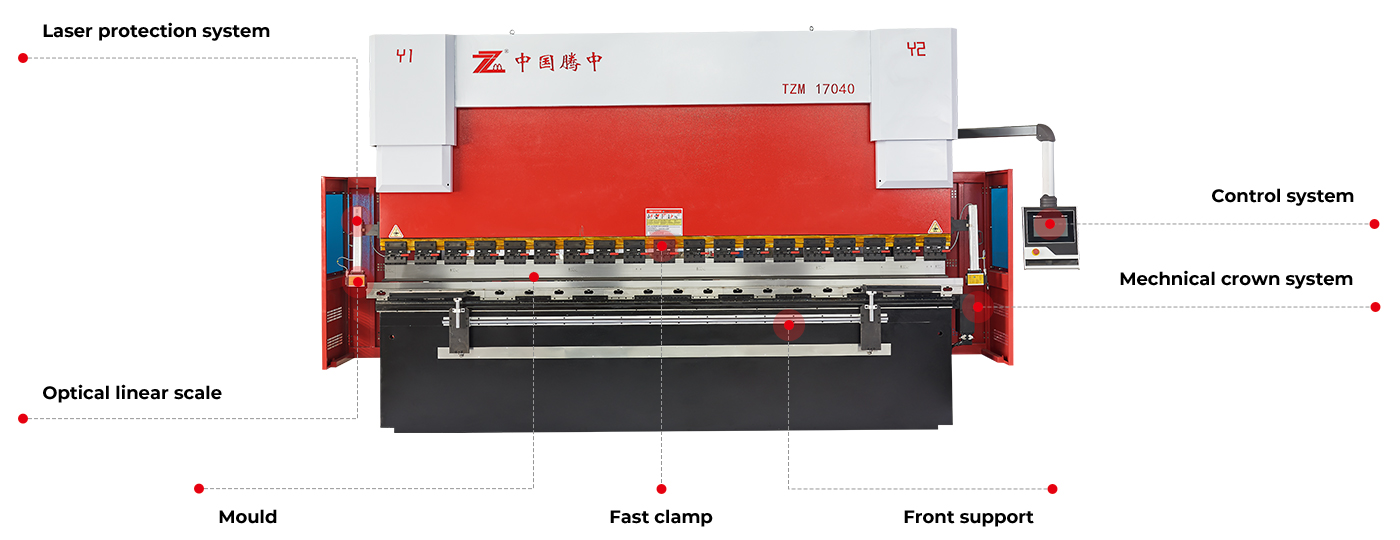

- Advanced Automation and Control Systems

- One-to-one Service from Engineers

- FOB, CIF, and DDP Price